ANMOPYC 2025 International Press Reverse Mission

Once again this year, ANMOPYC, with the support of ICEX, is organising a new international press reverse mission aimed at giving participating media outlets a first-hand look at the facilities, production processes and innovations of our member companies.

Through

this activity, ANMOPYC aims to enhance and reinforce the image of Spanish

machinery and equipment for construction, public works and mining worldwide,

promote our sector, as well as the experience of Spanish companies and the

technology of their products, and highlight the quality of Spanish equipment.

In this edition, we received the following editorials:

NorthAmerican Mining magazine - United States

NBM&CW- Infrastructure Construction Magazine - India

SOBREORUGAS - Mexico

M&T - Brazil

Revista Makinaria Pesada - Colombia

Our activity began on Monday

27 October with a visit to Carod, a

company with extensive experience in the manufacture of specialised machinery

for diesel and petrol engines, which has become a leading manufacturer of

products such as generator sets, high-pressure hydro cleaners, motor pumps and

pneumatic compressors, among others. Its work philosophy is based on the

manufacture of high-quality, robust, functional machines that respond to both

the standard machine market and special applications developed to meet the

needs of each customer.

During the visit, we

toured its modern 20,000 m2 facilities, where it carries out a technologically

advanced production process in which manufacturing, quality control, logistics

and R&D&I are fully integrated. We also saw first-hand its latest projects

and solutions and watched one of its compressors in operation.

We then continued with a visit to Teltronic, a company that designs, manufactures and implements the most comprehensive and innovative professional wireless communications solutions on the market, based on TETRA, LTE and 5G technologies. The robustness and reliability of its products, designed and manufactured in Europe, together with its ability to adapt to customer needs and its portfolio of services, are the strengths that have made Teltronic the trusted brand of critical communications professionals around the world.

During the presentation

and subsequent visit to its facilities, where more than 400 employees work, 125

of whom are in R&D, journalists were able to learn about the solutions the

company offers for the mining sector,

where operations are carried out in adverse conditions in an isolated,

extreme and complex working environment, from the changing terrain of open-pit

mines to the network of tunnels several hundred metres below ground in other

underground mines. This makes the design of the solution in terms of coverage,

reliability, robustness and traffic capacity an essential engineering activity

that Teltronic offers its customers.

.jpg)

To conclude the first day, we visited the facilities of Up Lifting, a company specialising in the supply of forklift trucks and reach stackers to provide solutions for handling general cargo and ISO containers in industries such as general logistics, maritime and intermodal transport, for both the civil and military sectors. During our visit to their two plants, we were able to see their engineering department, their fully integrated manufacturing facility, equipped with the most modern and precise production resources, as well as their complete traceability system, which allows them to provide their equipment with the quality demanded by the sector and expected by their customers.

On the second day of the

event, on Tuesday 28 October we visited the FundaciónHidrógeno Aragón ,

where we were given details of the new projects and technologies they are

working on related to the generation, storage and transport of hydrogen for use

in fuel cells, transport applications and distributed energy generation, and we

were shown their modern and functional facilities. Visitors were also able to

learn more about the H2MAC project

in which ANMOPYC is participating. The aim of this project is to demonstrate

the performance and reliability of a complete hydrogen fuel cell propulsion

system in two newly designed non-road mobile machinery (NRMM) units, an

excavator and a crusher, in difficult environments where access to electricity

is limited, such as mines and construction sites.

Our second meeting of the day took us to Cintasa, an Aragonese company specialising in the design, manufacture and assembly of belt conveyors and all their variants for a wide variety of sectors and markets around the world.

During

the visit, we had the opportunity to visit their technical office, where they

develop reliable and safe solutions tailored to the specific needs of each

customer, as well as their production facilities, where we were able to see

their wide range of high-quality equipment with their own exclusive designs.

During the visit, we were shown the latest projects they are working on for

different sectors and locations. The company also has its own specialised staff

for assembly, maintenance and technical assistance, guaranteeing total safety

in the proper functioning of our equipment.

The

third day began on Wednesday 29 October with a visit to the facilities

of LLamada, a company with more than 150 years of

experience in the metallurgical sector. After more than four decades of

innovation in the world of heavy machinery, its drilling equipment is now

considered the most efficient and cost-effective by the most demanding and

specialised companies in the foundation and piling sector.

Its range of equipment, specifically designed for drilling and built to last, consists of continuous flight auger (CFA) drills, displacement piles (FDP), secant piles (CSP), down-the-hole hammers (DTH), and SOILMIXING soil improvement equipment.

We

then moved on to the facilities of the TGB Group, a company specialising

in the design and supply of high-precision components for motion and automation

systems. Through its engineering capabilities, global production network and

extensive experience in the sector, has positioned itself as an international

benchmark in the development of patented slewing units, slewing rings,

hydraulic components and linear solutions for sectors as diverse as heavy

machinery, renewable energy, robotics and industrial automation.

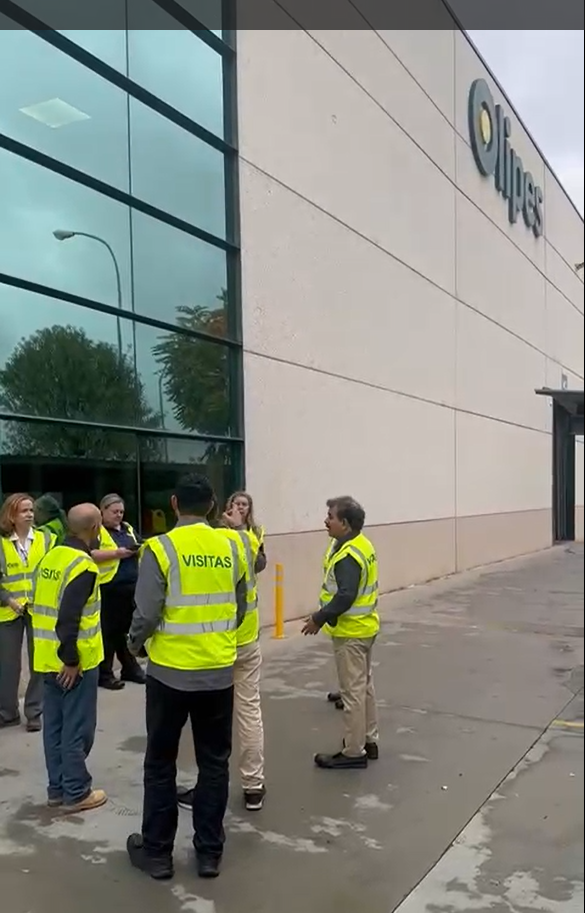

On Thursday 30 October, on our fourth day, we

first visited Olipes, a company specialising

in the development of top-quality lubricants, greases and special products for

sectors such as mining, public works, industrial vehicles and automotive, among

others. The company is known for offering sustainable products and services

with high added value in globalised industrial markets, seeking customer

satisfaction and the well-being and development of society. During the visit,

we were able to learn in detail about the company's entire production process,

its wide range of products, and its plans and projects for the future.

Our agenda then took us

to the headquarters of ICEX, a

public business entity whose mission is to promote the internationalisation of

Spanish companies in order to contribute to their competitiveness and add value

to the economy as a whole, as well as to attract foreign investment to Spain.

ANMOPYC is a collaborating entity, as it is an export association that carries

out foreign promotion activities within the construction machinery sector and

has substantial export representation.

During the visit, we had the opportunity to hold a meeting with the entity's Infrastructure and Industrial Technology managers, in which the journalists carrying out the activity were able to share their experiences, concerns and points of view on this mission and on the situation of the sector, as well as learn first-hand about the promotional activities that ICEX is carrying out in their countries.

And to conclude our 2025

international press mission, on Friday 31 October we visited Putzmeister Underground, a

company that develops, manufactures and exports concrete spraying equipment for

tunnel and underground mine support worldwide, complemented by concrete

transport and mixing equipment and utility equipment, with the clear objective

of offering a range of robust and versatile equipment that meets the specific

needs of each customer, providing them with effective and durable solutions.

During the visit,

international journalists were able to see first-hand the company's extensive

facilities, its production processes and technological innovations that reflect

Putzmeister's commitment to excellence, quality and national engineering. They

also held a meeting with its Technical Director, who shared his experience in

equipment development, innovation projects and other topics of great relevance

and interest, such as the situation in the sector and alternatives to fossil

fuels for this type of machinery.

ANMOPYC would like to express its sincere gratitude to all the companies participating in this activity for their time and attention during all the visits and for their willingness to show us in detail their products, production processes and projects in which they are involved.

Earthmoving, Compaction, Materials handling and Transport

Earthmoving, Compaction, Materials handling and Transport

Machinery for Mining and Construction Special Works

Machinery for Mining and Construction Special Works

Plants and Machinery for the Production of Construction Materials

Plants and Machinery for the Production of Construction Materials

Light and Auxiliary Equipment

Light and Auxiliary Equipment

Lifting Equipment for Persons and Loads

Lifting Equipment for Persons and Loads

Auxiliary Equipment and Elements

Auxiliary Equipment and Elements

Components, Spare Parts and Accessories

Components, Spare Parts and Accessories